Our professional team of design engineers will create, design and analyze your products to ensure you maximize productivity in a cost effective way. We use 3D design to check dimensions and ensure detailed designs are without error and graphically display dimension status on 2D drawings. Automatic interference and collision detection makes sure all parts fit together before you build a physical prototype, reducing cost and shortening the overall design cycle for faster time to market. It will also prevent the chance of a product being incorrectly designed.

“Stand out from the crowd and beat off competition”

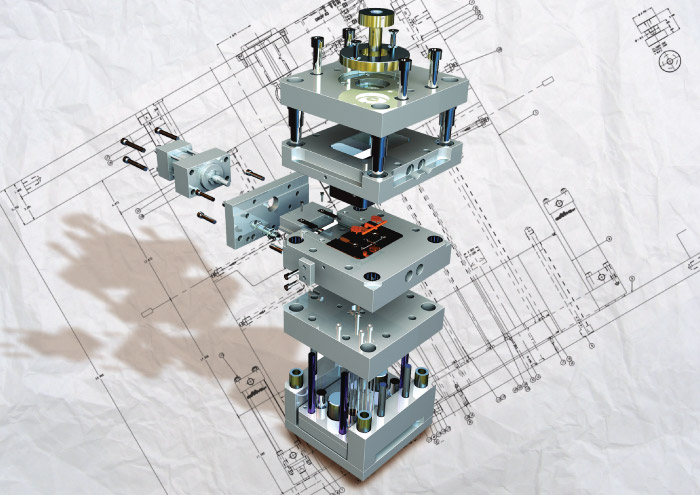

3D data can be used to help you to create dynamic technical communications and exploded formats, making your projects compelling and unique.

Our team is experienced in consumer and commercial products, machine, tool design and all aspects of manufacturing development. We offer a comprehensive range of solutions providing access to many virtual fields of engineering simulation that a design process requires. We will analyze your products using latest advanced Simulation Technology.

What it is? Computer simulation technology is the discipline of designing a model of an actual, theoretical physical system, executing the model on a digital computer, and analyzing the output. To understand the reality and all of its complexity, we build artificial models and dynamically act out roles with them. Within the overall task, there are three primary sub-fields that we do for you: model design, model simulation and post-processing.

Using a Solid modeler CAD program, a mathematical model can be created which represents a physical object or an assembly. For example: tools, pipes, dies, punches etc. It is the best way to check dimensions and ensure designs are error free and display dimensions on 2D drawings.

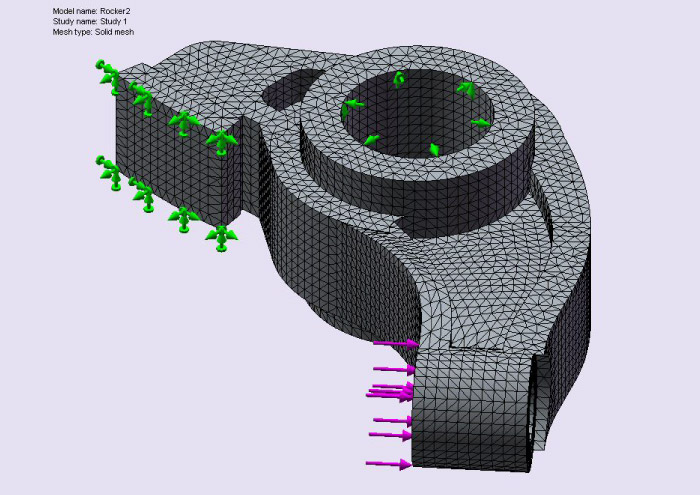

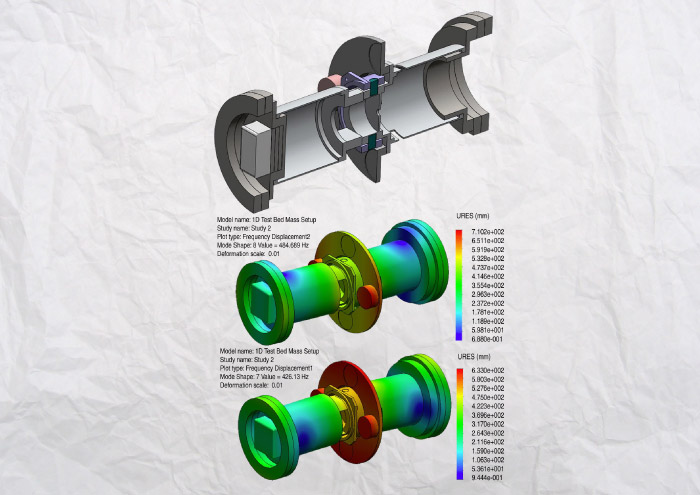

The designed model then can be simulated on a computer using Finite Element Analysis (FEA) and / or Computational Fluid Dynamics (CFD). Providing data and the initial conditions, you can see how the designs will behave as physical objects. With pipes, we model the fluid flow and the heat transferred enabling us to conduct tests on virtual prototypes.

Post processing of finite element data is requested to organize the output in an easily understandable way. It provides simulation analytics, data visualizations such as stress concentration, temperature, velocity etc.

Our design platform can offer solutions that can help all commercials industries.

Engineering Services, Industrial Machinery & Heavy Equipment, Manufacturing, Mold, Tools & Die, Oil & Gas, Process & Plant, Constructions & Scaffolding, Consumer Products, Alternative Energy, Piping, Plastic, Furniture & Woodworking, Electronics, Aerospace, Automotive, Medical Science and much more.

The big advantage is reducing time-to-market, efficiently utilizing manpower resources, optimizing the use of materials and achieving quality standards.